Well, here it is #4 heading out to my friend tomorrow. This guitar is traded for a website, design and update by a good friend of mine.

Intro:

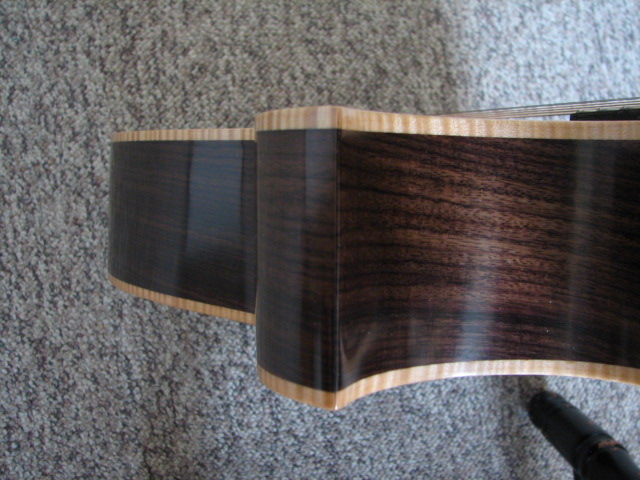

EIR Back and Sides, Western Red Cedar Top, Maccasser Ebony fretboard, bridge and head stock veneer, 5 piece laminated neck Honduran Mahogany, Maple, Rosewood, single action truss rod (adjusting at the nut as you can see), flamed maple binding with b/w/b purfling on the top, EIR rosette with b/w/b purflings lines, standard Schaller chrome tuners, MOP headstock logo and customer signature at the 12th fret.

Finish is mohawk classic instrument lacquer over bulls eye premixed shellac.

Dimensions: 16" lower bout, 11-1/2" upper bout, 9-1/2" waist, 20" body length, 25.4 scale, 4-1/4" at the tail, 3-1/4 at the neck joint.

Firsts for me:

Pearl inlay work, the entire finish job (that I am happy with).

Things i'm realy pleased with: The body mitter at the cutaway, the signature (95% satisfied), the finish (95%, to chicken to try high gloss), the playability and the sound.

Things i'm not so please with: well, I'm not telling.

Thanks for looking